Business and Workforce Solutions

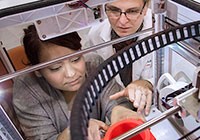

Every organization wants to be stronger and more productive. Partner with Business and Workforce Solutions (BWS) at Gateway Technical college to make it happen. Narrow skill gaps, develop leaders, boost productivity and ultimately build an engaged workforce in any area – from manufacturing teams to the C-suite. We can assess the skill levels of your employees, guide leadership through strategic options and develop specialized training to foster the outcomes you want, where and when you need them.